Win the Next Decade: Why Strategic Instead of E&I automation write Electrical & instrumentation for RDF boiler Matters now

With increasing global energy demand for waste-to-energy and an accelerated pace of industrial decarbonisation, the 2026–27 investment cycle for Refuse-Derived Fuel (RDF) boilers is entering a transformative phase.

For plant managers, engineering heads, E&I specialists, and procurement leaders, the coming months will play a key role in shaping how plants strengthen competitiveness, operational stability, and compliance readiness.

This guide outlines a strategic E&I investment framework used in RDF boiler facilities.

It serves as a bridge between technical execution and business outcomes — a roadmap for decision-makers aiming to position electrical panels, control systems, and instrumentation as drivers of profitability, compliance assurance, and operational resilience.

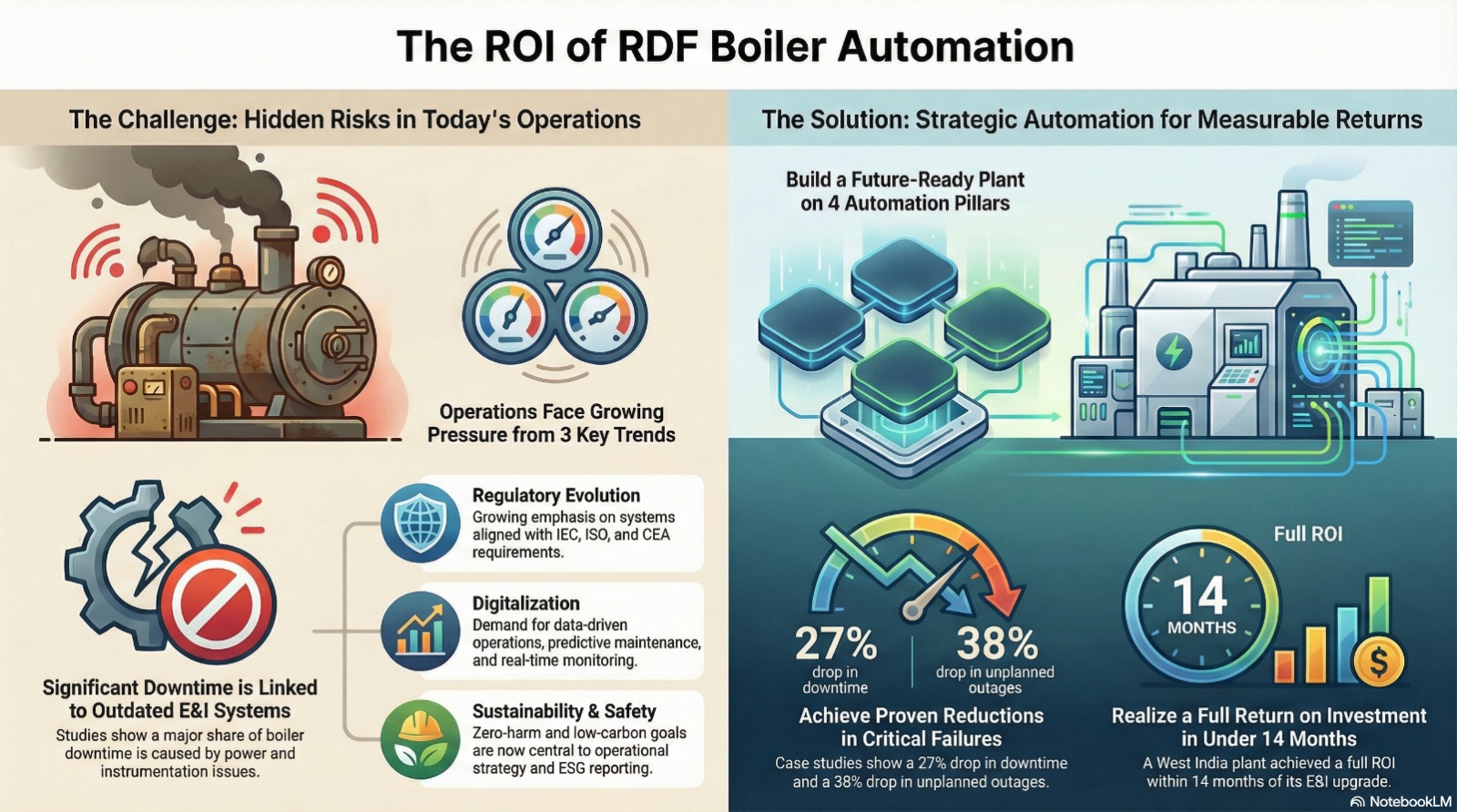

The Business Case: Automation as Strategic Leverage

In 2026, industrial automation is increasingly viewed not only as a cost element, but as a strategic opportunity for long-term value creation.

IEEE and industry studies indicate that a significant share of RDF boiler downtime is associated with power and instrumentation performance, highlighting the importance of modern panels, integrated automation, and well-maintained safety systems.

Example

A 60 TPD RDF boiler in North India experienced recurring production interruptions due to tripping events. As part of a modernization initiative, the plant upgraded to IEC-certified smart electrical panels.

Within six months, downtime reduced by 27% and productivity improved measurably — contributing to higher operational reliability and financial stability.

The takeaway is clear: Reliable, data-enabled E&I automation supports stronger ROI, compliance confidence, and long-term asset readiness in an environment of tightening carbon and performance standards.

What Is Shaping RDF Boiler Automation in 2026–27

Three global and regional trends are influencing how RDF boiler plants approach E&I investments:

- Regulatory Evolution

There is growing emphasis on safety-certified, future-ready systems aligned with IEC, ISO, and CEA requirements.

Staying aligned with evolving standards helps plants manage compliance expectations and insurance assessments more smoothly.

- Digitalization and Data-Driven Operations

Modern DCS and SCADA systems enable predictive maintenance, real-time monitoring, and continuous improvement through data.

This is especially valuable for multi-site operations or facilities with limited on-shift supervision.

- Sustainability and Safety Priorities

Zero-harm and low-carbon goals are now central to operational strategy. Precision instrumentation and safety interlocks support compliance and contribute to ESG reporting, strengthening investor confidence and sustainability performance.

Together, these dynamics position E&I automation as a cornerstone of future-ready RDF plant strategies.

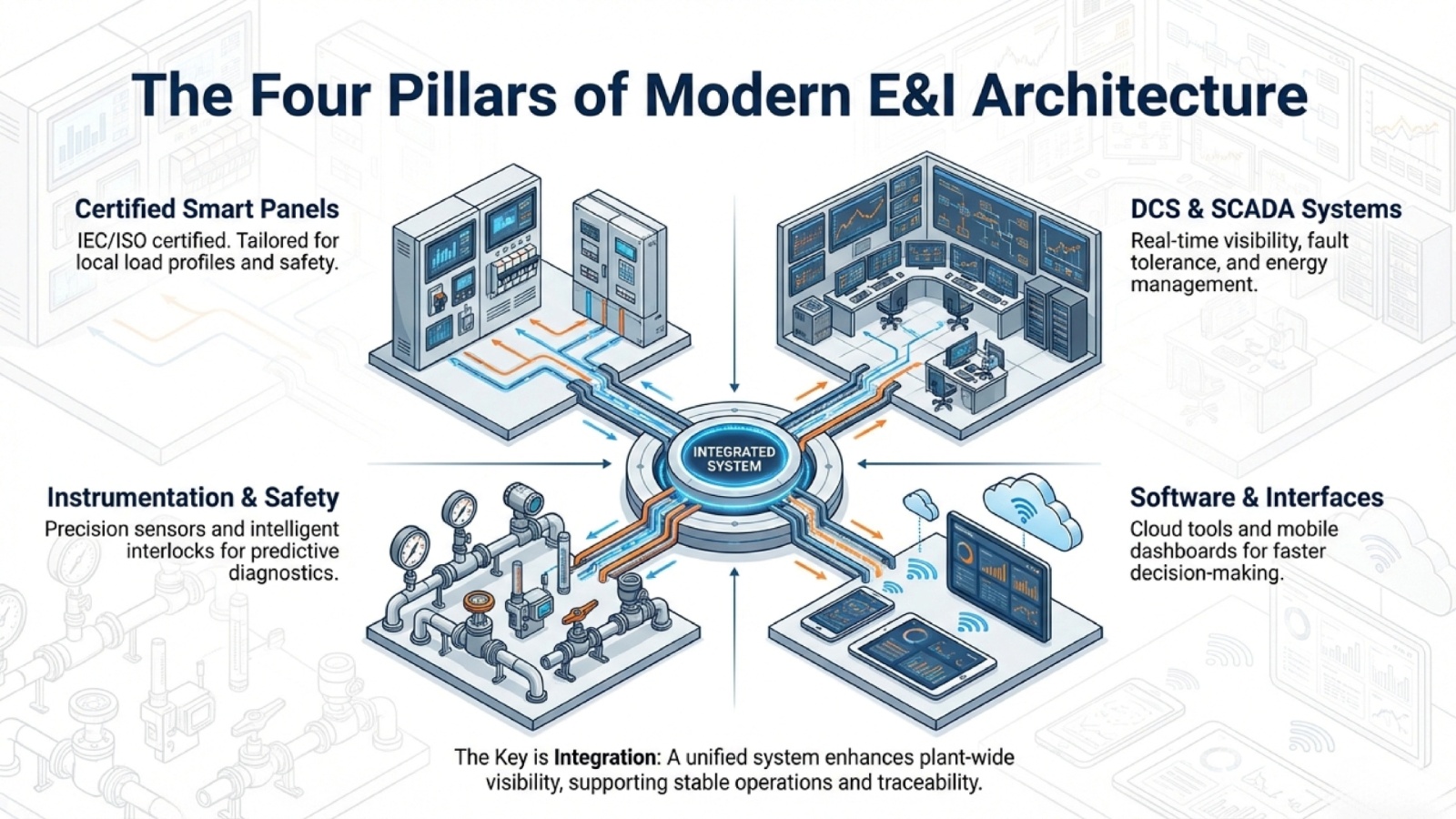

What Matters Most in 2026: E&I Automation Priorities

RDF and waste-to-energy boiler facilities increasingly benefit from automation systems built around four key pillars:

- Certified Smart Panels

IEC- and ISO-certified panels designed for local load profiles, safety requirements, and energy performance.

- DCS & SCADA Systems

Integrated control systems that deliver continuous data visibility, fault tolerance, and real-time energy management.

- Instrumentation and Safety Systems

High-precision sensors, flow transmitters, and intelligent interlocks supporting predictive diagnostics and optimized control.

- Software and Interfaces

HMIs, mobile dashboards, and cloud-enabled tools that allow faster, data-driven decision-making.

The key is integration.

A unified system enhances plant-wide visibility and coordination, supporting stable operations and traceability over time.

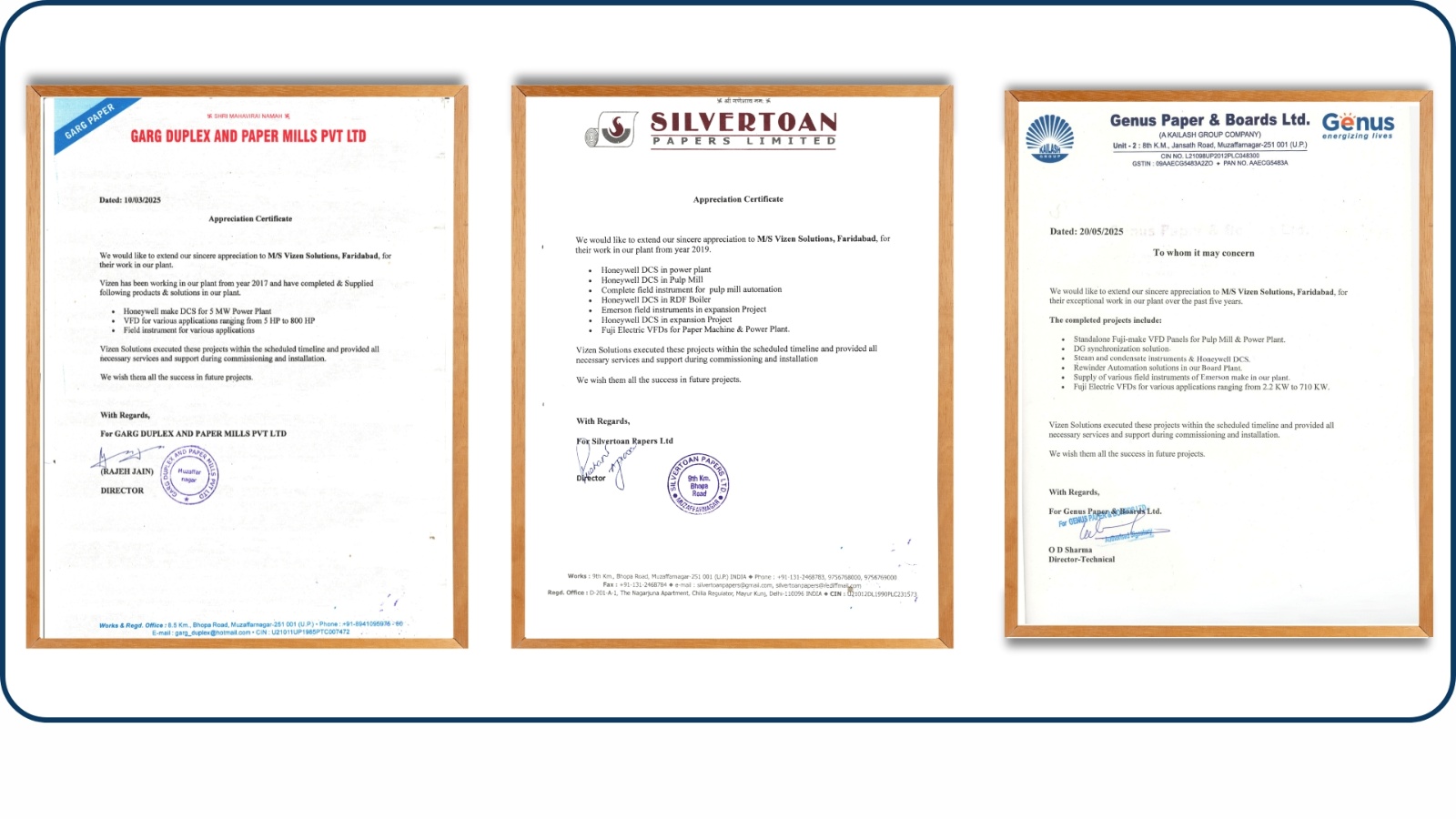

Proven Value: Why Vizen Solutions Leads the Industry

The choice of an E&I partner plays a significant role in long-term plant performance.

Vizen Solutions’ automation and engineering services deliver:

- Extensive Industry Experience — Over 15+ RDF projects & 35 Power plant , paper, and biomass boiler projects, reflecting proven performance across diverse operating environments.

- Custom Engineering — Panel and automation designs tailored to each plant’s load profile, process layout, and future expansion plans.

- High ROI and Effectiveness — Clients report measurable improvements in fuel-to-power efficiency and downtime reduction.

- Full Integration Services — End-to-end execution from panel manufacturing to commissioning, supporting streamlined project delivery.

- Compliance with Global Standards — Alignment with IEC, ISO, and CEA codes, supporting asset longevity, investor confidence, and access to green finance.

- Strategic Partnerships — Collaborations with Honeywell , Fuji & Siemens and Emerson for high-quality components and global support.

Appreciation Certificate from Industry Leader

A Framework for ROI-Based E&I Investment Decisions

A structured five-step evaluation model helps align automation investments with business goals:

- Technical Fit and Regulatory Alignment

Confirm IEC, ISO, and CEA compliance and assess scalability for future capacity upgrades or co-firing options.

- Reliability and Performance

Review vendor data on uptime improvement and compatibility with predictive maintenance systems.

- Lifecycle Cost and Support

Evaluate five-year total cost of ownership, including spares, inspection, and service, with local and remote support availability.

- Vendor Credibility

Review case studies, performance references, and quality documentation.

- Business Impact Modelling

Estimate measurable benefits such as reduced downtime, improved output, and ROI timelines.

Example

A North Indian India RDF plant implemented next-generation control panels and instrumentation. Within 12 months, it achieved:

- 38% reduction in unplanned outages

- Improved safety compliance

- ROI within 14 months

Strengthening Alignment Across Teams

As systems evolve, aligning modernization goals with practical execution helps improve coordination and capital efficiency.

- For Engineers and Operators — Condition-based monitoring using DCS and SCADA analytics enhances operational insight.

- For Procurement Managers — Panel specifications and certifications support warranty coverage and insurance considerations.

- For Finance and Investment Teams — Well-planned E&I investments help manage long-term operating costs and compliance exposure.

Integration across engineering, operations, and finance supports sustainable and profitable plant performance.

Investing for Resilience, Compliance, and Growth

As policies continue to promote cleaner energy and waste recovery, RDF plants that advance their E&I capabilities early are positioned for compounding returns — operationally and financially.

Measured benefits of E&I modernization include:

- Improved plant availability through condition-based automation

- More efficient energy flow and streamlined compliance reporting

- Extended equipment life and reduced maintenance interventions

- Stronger safety performance and audit readiness

From Insight to Action

A data-driven, standards-compliant E&I automation strategy helps future-proof RDF boiler operations.

At Vizen Solutions, we support this journey through:

- Detailed plant process assessments

- ROI-oriented automation roadmaps

- Vendor-neutral technology guidance

Looking to upgrade or design an RDF Boiler Automation system?

Our team at Vizen Solutions helps waste-to-energy plants improve reliability, safety, and ROI through customized RDF boiler automation solutions.

Connect with us at:

+91-9910322011