Electrical Panel Manufacturer for RDF Boiler: What Every Plant Manager Knows

All RDF boiler projects begin with excitement. Waste-to-energy is about converting what would have gone to landfills into useful steam and power, supporting sustainability while strengthening energy independence.

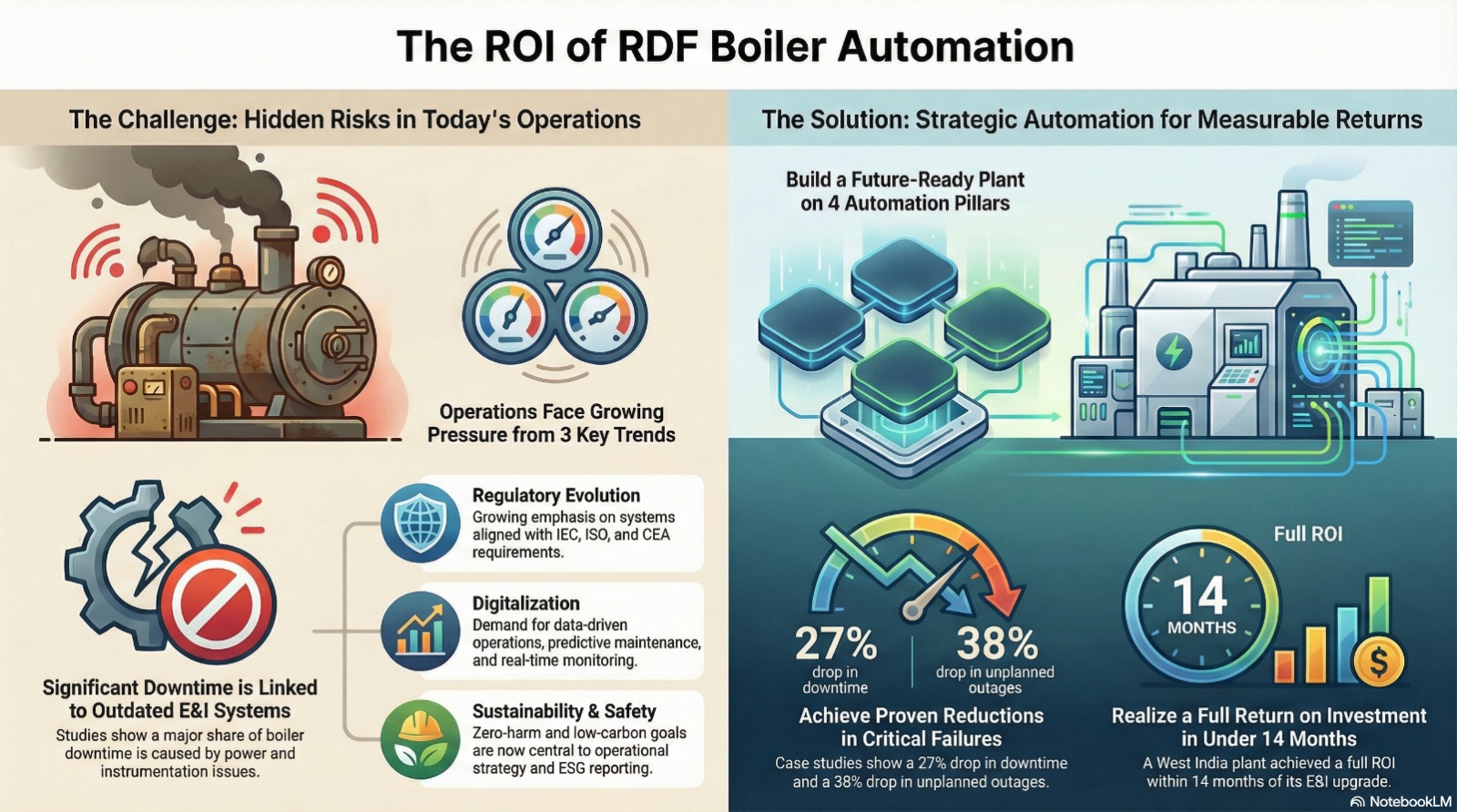

From our experience across RDF installations, consistent boiler performance relies heavily on how well the electrical and control systems are engineered and integrated.

It is often the electrical panels, MCCs, PCCs, and DCS integration that quietly influence how smoothly an RDF boiler performs over time, especially under real operating conditions.

What We’ve Observed While Working with Plants and Plant Managers

Managing an RDF-fired power plant involves multiple interdependent systems operating under highly variable conditions. Through our work with RDF boiler installations across India and international markets, we’ve observed that successful plant operation depends less on isolated equipment performance and more on how well systems are sized, integrated, and planned for long-term use.

Based on discussions with plant managers and hands-on project experience, three focus areas consistently stand out when it comes to reliable and efficient RDF boiler operations:

- Panel Sizing Considerations: Electrical panels must be designed to comfortably handle RDF’s fluctuating operating loads. Proper sizing of drives, starters, and feeders reduces nuisance trips, thermal stress, and premature component failure.

- Integration Depth: Effective alignment between mechanical systems, field instrumentation, and electrical controls is critical. Shallow integration often leads to delayed responses, control instability, and avoidable operational inefficiencies.

- Lifecycle Planning: Panels that perform well during commissioning deliver greater value when designed with long-term operating cycles, maintenance accessibility, and future upgrades in mind.

This blog outlines the key aspects plant managers evaluate when selecting an electrical panel manufacturer for RDF boilers—covering design requirements, Factory Acceptance Testing (FAT), operation and maintenance considerations, and tender evaluation criteria.

Electrical Considerations Specific to RDF Boilers

Variable operating loads

RDF boilers differ significantly from coal or biomass systems due to the inherent variability of the fuel mix.

Plastic ignites quickly, cardboard burns slower, and tyres require longer residence time. As the grate and feeding system adjust, the drives experience continuously changing torque requirements.

Frequent Start–Stop Cycles

Conveyors, feeders, and grate drives rarely operate at steady state. Panels must handle surges and transients smoothly and consistently during changing operating conditions.

Challenging Environments

Dust, heat, and vibration around RDF boilers mean panels benefit from protection levels beyond basic industrial standards.

Critical Uptime

Downtime is not limited to loss of power. It can lead to clinker formation, unstable combustion, and rising recovery costs. The electrical environment must absorb unpredictability while delivering consistent and predictable control. This is where panel design demonstrates its long-term value.

Safety Considerations

When designing RDF handling and boiler areas, proper zone classification is essential. Flameproof or enhanced protection enclosures are selected based on operating conditions and fuel characteristics to support safe and reliable power distribution across these zones.

At Vizen Solutions, our approach reflects the realities of these operating environments. Panel design focuses on stable performance, safety, and long-term reliability.

Our MCC panels for RDF boilers include coordinated protection and real-time status feedback for early fault detection, thermal motor protection through overloads, short-circuit protection, phase monitoring, and short-circuit-withstand designs validated with tested busbar ratings and certified components. Layouts are planned for effective cooling, safe servicing, and future expansion.

Design Criteria and Standards to Expect from Your Panel Manufacturer

When we assess or fabricate panels for RDF boiler projects, we focus on the following:

Drive Sizing with Margin

Grate and fuel-feeding drives are selected above average load levels, with coverage for heavier RDF batches encountered in practice. Field experience shows appropriate drive sizing plays a major role in feeder reliability.

Harmonic Management

With multiple VFDs in operation, harmonic filtering and well-designed bus work help avoid unnecessary heating, protection activations, and transformer stress over time.

Segregation of Feeders

Critical feeders such as ID fans, FD fans, and grate drives are segregated from non-critical loads so isolated trips do not cascade into boiler shutdowns.

Smart Protection Architecture

Protection schemes extend beyond basic fuses and MCBs, combining differential protection, thermal overloads, and instantaneous relays to safeguard equipment proactively.

Standards Compliance

Panels are designed in line with IEC 61439, with flameproof enclosures for hazardous areas and CPRI/ASTA-certified busbar ratings.

Operator Interface Integration

Live current, torque, and status visibility through DCS/SCADA help operators extract the full value of the panel. These design choices translate directly into uptime, safety, and predictable combustion.

FAT Testing and Commissioning: Where Reliability Is Proven

Panels are ultimately validated in real operating conditions. This is why comprehensive Factory Acceptance Testing (FAT) is essential.

Key FAT checks include:

- Heat run tests to confirm busbars, breakers, and connections perform at rated currents

- Functional interlocks ensuring correct operational sequencing

- Communication testing for Modbus, Profibus, or Ethernet links to DCS

- Load simulations under variable torque conditions representative of RDF feeding

During commissioning, frequency analysis verifies grid stability, protective relays are calibrated to site-specific requirements, and full DCS integration ensures a unified operational view.

We have seen that panels benefit greatly from thorough FAT under simulated operating loads before entering service.

O&M and Lifecycle Costs: Designing for Long-Term Value

Electrical panels represent a long-term investment. Certain design choices can influence OPEX over the years.

Examples include:

- Busbar sizing impacting heat buildup and insulation life

- Modular designs allowing quick feeder replacement

- Condition monitoring to identify overheating or breaker wear early

- Event logging that explains exactly why a feeder tripped

One RDF client reduced annual downtime by nearly 400 hours, not by changing the boiler, but by improving panel visibility and serviceability.

Tender Evaluation: Balancing Technical and Commercial Value

Cost is often an important factor during tender evaluations. Lifecycle performance and operating costs, however, deserve equal attention.

Technical evaluation (70%)

- IEC/CPRI/ASTA compliance

- Drive sizing margins

- Harmonic mitigation

- Feeder segregation

- DCS/PLC integration

- FAT transparency

Commercial evaluation (30%)

- Base price

- Warranty

- Spare availability

- After-sales support

This balanced approach helps select a partner that adds value over the life of the installation.

Case Insight: Panel Design Supporting Performance at a Paper Mill

At a kraft paper mill, monthly downtime had reached 30–40 hours. Further evaluation showed that electrical system optimisation offered a strong opportunity for improvement.

Motors were upgraded to handle cyclic torque, critical feeders were segregated, and torque and breaker status were integrated into the DCS. Within three months, downtime reduced by 65% and boiler efficiency improved from 66% to 72%. Teams shifted focus from recovery to optimisation.

This reinforced an important insight we have consistently observed: reliable combustion is strongly supported by reliable electrical systems.

Closing Thoughts

Selecting an electrical panel manufacturer for RDF boilers is not only about price. It is about designing for reality, testing for reliability, and supporting the full lifecycle.

Handled well, panels help stabilise RDF variability, reduce nuisance trips, save downtime, lower OPEX, and support compliance and export readiness.

At Vizen Solutions, we focus on aligning plant reality with system design, supporting mills in building long-term stability and sustained performance through turnkey electrical EPC, DCS integration, and lifecycle support.

If your plant is planning a new RDF boiler or panel upgrade, we would be glad to share practical insights from similar projects.

The real strength of an RDF boiler is not only in the furnace, but in the electrical systems that quietly keep it running every day.

If you’re planning an RDF boiler project or panel upgrade, speak with our team to review electrical design, FAT scope, and lifecycle risks before finalising decisions.